Chip production takes hundreds of steps, and any step error can cause device failure. Therefore, the chip inspection process is crucial, and the use of good chip test equipment and methods is one of the keys to improving the level of chip manufacturing. At the same time, whether the integrated circuit design is reasonable and the product is reliable, it needs to be verified by the function and parameter test of the integrated circuit.

First, the three core devices of integrated circuit chip testing

Equipment manufacturing is the basic industry of integrated circuits. It is the key to complete wafer fabrication, packaging and testing, and advancement of integrated circuit technology. In the investment in integrated circuit production line, equipment investment accounts for about 80% of total capital expenditure (SEMI estimate).

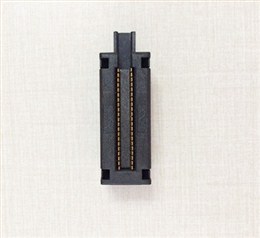

The special equipment required mainly includes the lithography machine, chemical vapor deposition (CVD) equipment, etching machine, ion implanter, surface treatment equipment, etc. required for the wafer manufacturing process; the cutting and thinning equipment required for the packaging process, Measure defect detection equipment, bond packaging equipment, etc.; test machine, sorting machine, probe station, etc. required for testing; and other diffusion, oxidation and cleaning equipment required for front-end processes. The manufacture of these devices requires the comprehensive use of optical, physical, chemical and other scientific technologies, with high technical content, manufacturing difficulties, and high equipment value.

The test equipment of the integrated circuit mainly includes a test machine, a sorting machine and a probe station. As an important special equipment, the integrated circuit test equipment can not only judge the eligibility of the tested chip or device, but also provide information on the weak links in the design and manufacturing process, which helps to improve the level of chip manufacturing. Among them: the test machine is a special device for detecting the function and performance of the chip. The test machine applies an input signal to the chip, and the output signal of the tested chip is compared with an expected value to determine the effectiveness of the function and performance of the chip under different working conditions.

Second, the technical difficulties of the chip test equipment:

The integrated circuit industry is a technology-intensive, knowledge-intensive high-tech industry that combines computer, automation, communications, precision electronic testing, and microelectronics. Integrated circuits have high requirements for reliability, stability, and consistency. The requirements are higher. Therefore, the technical barriers of integrated circuit test equipment are high.

(1) Test machine

1) As integrated circuit applications become more widespread, the demand is getting larger and larger, and the test cost is higher and higher, so the testing speed of the test machine is higher and higher (such as the response speed of the source reaches microseconds). level);

2) Due to the increasing number of integrated circuit parameter items, such as voltage, current, time, temperature, resistance, capacitance, frequency, pulse width, duty cycle, etc., there is an increasing demand for test machine functional modules;

3) Status, test parameter monitoring, production quality data analysis, etc., combined with the application of big data, put forward higher requirements for data storage, acquisition and analysis of test machines.

4) The customer's requirements for integrated circuit test accuracy are getting higher and higher (microvolt, micro-ampere precision), such as the tester clamp accuracy requirements from 1% to 0.25%, time measurement accuracy to microseconds, test Machine test accuracy requirements are becoming more stringent;

5) The increase of the number of integrated circuit products requires that the test equipment has a generalized software development platform to facilitate the customer to develop secondary application programs to meet the testing needs of different products.

(2) Sorting machine

1) The diversity of integrated circuit package forms requires the sorter to have the ability to quickly switch when testing integrated circuits of different package forms, thereby forming a strong flexible production capacity and adaptability;

2) Due to the miniaturization and integration features of the integrated circuit, the sorting machine has high requirements for automatic high-speed repetitive positioning control and pressure measurement accuracy, and the error accuracy is generally required to be 0.01mm;

3) The batch automation of the sorter requires strong operational stability, such as high requirements for UPH (number of integrated circuits per hour) and Jam Rate (downtime ratio);

4) The integrated circuit test has certain requirements for the external test environment. For example, some integrated circuit test requirements are carried out in a variety of temperature test environments of -55-150 ° C, no magnetic field interference test environment, and a variety of external field superimposed test environments. How to give Setting the corresponding test environment is a technical difficulty for the sorter.

The sorter and probe station are special devices that connect the pins of the chip to the functional modules of the tester and implement batch automated testing. In the design verification and finished product testing, the test machine needs to be used together with the sorting machine; in the wafer inspection process, the test machine needs to be used together with the probe station.

(3) Probe station

1) Wafer inspection needs to have multiple sets of visual precision measurement and positioning systems, and has the functions of visual mutual calibration and multiple coordinate systems fitting each other;

2) The precision of the probe station is very strict, and the repeat positioning accuracy is required to reach 0.001mm (micrometer) level;

3) The probe station has high requirements on the cleanliness of the working environment of the equipment. In addition to the fully automated operation with almost no intervention, the requirements for low dust of the transmission mechanism are required, and special functions such as airflow dust removal are required.

4) Wafer inspection requires high stability of equipment, and each actuator needs to be controlled for redundancy. The wafer damage rate is required to be controlled within 1ppm (parts per million);

Third, domestic test equipment companies are growing rapidly

As the core of the semiconductor industry, integrated circuit chips have developed rapidly in the past half century. The early integrated circuit companies were mainly based on the IDM model. The IDM model was also called the vertical integration mode, which is the IC manufacturer (IDM) designed and sold the finished chip after processing, packaging and testing. The integrated circuit chip industry chain began to develop into a vertical division of labor division of specialized division of labor.

With the increasing maturity of processing technology and the continuous improvement of the degree of standardization, the integrated circuit industry chain has begun to develop in the direction of specialized division of labor, gradually forming an independent chip.

Design companies (Fabless), foundry companies (Foundry), package testing companies (Package & TestingHouse), and formed a new industry model - vertical division of labor mode.

In the vertical division mode, design, manufacturing, and packaging testing are separated into separate segments of the IC industry chain.

According to the statistics of the International Semiconductor Association, in terms of global industrial chain distribution, revenue from chip design, wafer fabrication and packaging testing in 2015 accounted for 27%, 51% and 22% of the overall sales revenue of the industry chain. At present, although most of the top 20 semiconductor manufacturers in the world are still IDM manufacturers, such as Intel, Samsung, Toshiba, Texas Instruments, ST, etc., due to recent years The cost of semiconductor technology research and development and the cost of investment in wafer production lines have increased exponentially. More IDM manufacturers have adopted the Fab-lite model, which is to commission wafer fabrication for manufacturing, and even become independent. Chip design companies, such as AMD, NXP and Renesas, have become the development direction of the semiconductor industry business model.

Shenzhen HongYiElectronics Co., Ltd. is mainly responsible for the overseas sales and international marketing of Kaizhitong products. It is a one-stop chip aging test solution manufacturer. If you want to know more about customized IC socket/fixture, please contact us:

Email:sales@andksocket.com

Skype:windy@hydz999.com

TQFP100 FQFP100 QFP100 burn in socket

TQFP100 FQFP100 QFP100 burn in socket High frequency socket-2.5GHz test socket

High frequency socket-2.5GHz test socket SMT/SMD capacitor burn in test socket

SMT/SMD capacitor burn in test socket TSOP48 burn in socket

TSOP48 burn in socket